Keen eyed locals may have noticed that the mill sails have been resting at an unusual angle this past week. This is because we have been paying our respects to HRH The Duke of Edinburgh in the traditional way.

For centuries, windmills have communicated messages to local communities by leaving the sails at rest in particular positions. The mourning position as shown above (taken this week) shows the top sails just over the highest point – showing life is “going down hill”, there is a reason for mourning.

When the top sail is set just before it reaches the highest point, there are reasons to celebrate, a birth has taken place or a marriage.

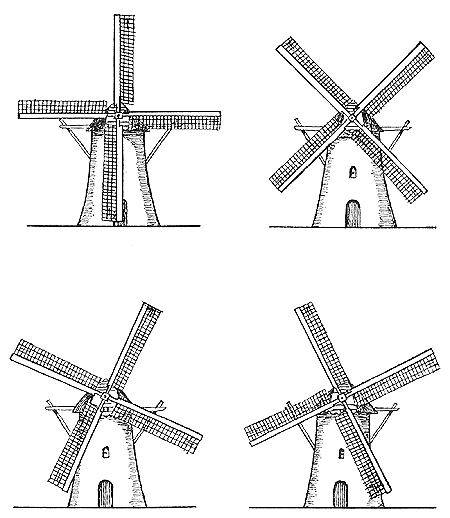

The image above is borrowed from our Dutch colleagues (who share the same symbols): Top Left = the miller is taking a short rest

Top Right – the miller is taking a longer rest (how the mill is usually left between milling sessions)

Bottom Left = reason to celebrate and Bottom Right = mourning.

Maintenance Progressing

You can also see in the photo above that we have made progress over the last three weeks repairing cracks in the mill tower and repointing where chunks of brickwork have split away due to frost damage over the winter. The north face of the mill is particularly susceptible to frost damage and was hit badly this year. So, we make the repairs, and then re-coat the tower in a tar-like substance to keep it water-tight.

The underside of the fanstage has also had a new coat of paint and the metalwork which supports the fan frame has been cleaned and painted!

If you’ve had to wait a little longer for your flour over the last couple of weeks, our apologies! We had a bumper crop of orders over Easter and also had to divide our time between milling and maintenance whilst we were loaned a Cherry Picker to enable us to access the outside of the tower. Normal service has now resumed!