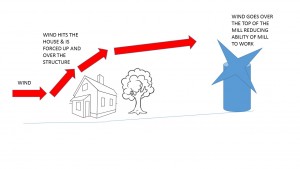

As you will have read in other posts on our Blog, we are objecting to a proposed development of 10 bungalows to the East of Fosters Mill because it will harm the wind supply to Fosters Mill from the only direction in which the mill receives unfettered wind – wind that is free from obstructions of buildings or trees and because of the impact such a development will have on the settings of two listed windmills.

A key part of our argument in terms of wind loss is that Fosters Mill is already badly impacted by tree and building pollution blocking the wind supply from most directions. The wind study we have commissioned suggests that this now blocks 80% of the wind the mill would have had before trees and buildings were erected around the mill.

This blog post shows video diaries taken to show the impact of this wind restriction and a video showing how clean the wind supply is from the East because it is currently free from obstructions (buildings and trees). The videos show days / times when Fosters Mill is not able to work because the wind is being obstructed by building and trees whilst other mills in the area – Wicken Windmill or Burwell Windmill are able to grind flour.

The final video, however, shows how clean and free from turbulence the wind is from the East. Contrast this to the penultimate video!

These videos are therefore clear evidence of the negative impact that trees and buildings have on windmills, preventing the mill getting the wind it requires to turn. The loss of wind from other directions amplifies the importance of the unfettered wind from the East North East to South East – the direction of the proposed development.

This video taken on the 30th July shows the mill facing west where trees and the water tower block the wind whilst at Wicken Windmill, you can see the mill working, grinding flour.

This video taken on the 24th June again shows the mill facing west.

This video taken on the 14th May shows the mill facing to the North West and shows Burwell Mill turning whilst Fosters Mill is not able to turn again due to wind loss through trees and buildings.

This video shows the impact of trees on wind turbulence – taken whilst the mill was facing west you can see how the gusts of wind caused by buildings knock the whole top of the mill (cap) from side to side. The proposed development and associated trees will cause more and more turbulence over time from a wind direction which currently creates no turbulence.

This final video shot whilst the mill is facing to the East shows the mill working in a very strong breeze, working hard – yet, the cap is steady, not affected by turbulence – that is because we currently do not experience turbulence because the wind is unfettered, free of obstructions and therefore clean and strong.